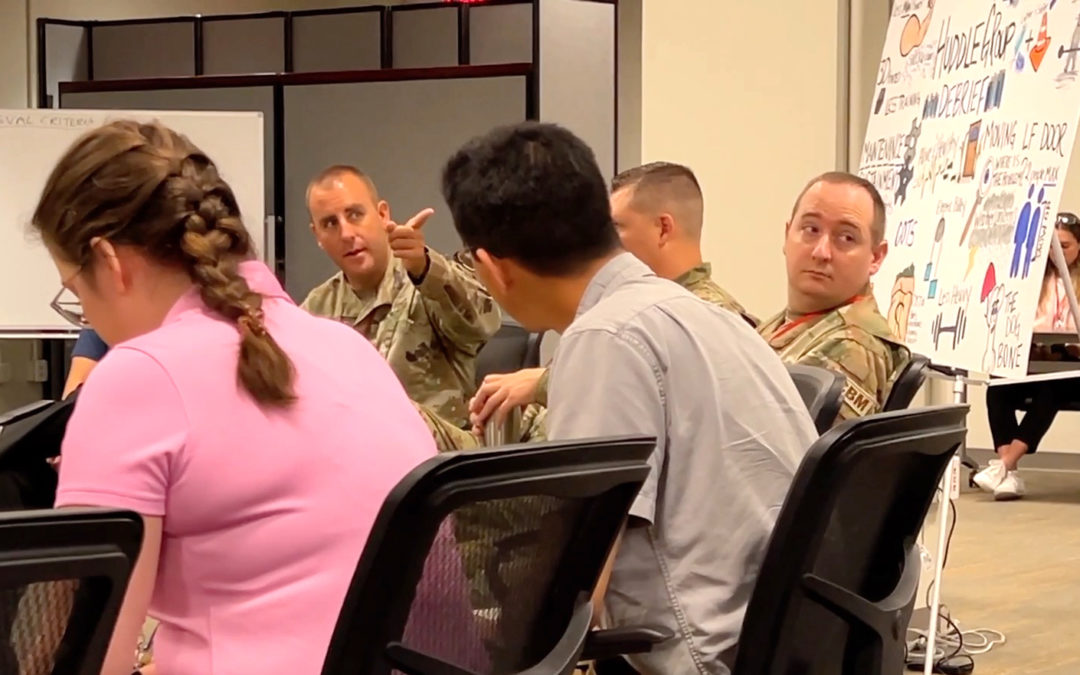

MSgt. Mike Holmes discusses the Better Enclosure Entry Facilitator project with a group of industry and academia during a problem definition workshop held at the Cyber Innovation Center, Bossier City, Louisiana, on July 7. (Sean Green/STRIKEWERX)

By Sean Green | STRIKEWERX Marketing and Communications Director

BOSSIER CITY, La. —STRIKEWERX, Air Force Global Strike Command’s innovation hub, brought together industry and academia to explore new technology for missile maintainers.

STRIKEWERX hosted a two-day Problem Definition Workshop at the Cyber Innovation Center in Bossier City, Louisiana, July 6 and 7. The workshop saw subject matter experts from government join 20-plus academia and industry participants to assist AFGSC and Air Force Nuclear Weapons Center with market research for the BEEF (Better Enclosure Entry Facilitator) project.

This project seeks to solve challenges with legacy equipment — the Hydraulic Pusher Set, also known as the Pipe Pusher — used to open and close the Intercontinental Ballistic Missile launcher closure door during maintenance.

The workshop used collaboration methods and techniques to have participants share their knowledge about current developments in mechanical engineering, hydraulics, electricity, and manufacturing.

Mark Conrad, program manager for BAE Systems and subject matter expert on the topic, said the workshop was valuable for breaking down the government’s needs and gained perspectives from different viewpoints.

“People from many different backgrounds helped us to see what’s out there to suit the government,” Conrad said. “It’s great for smaller companies to bring that innovation forward so we can all be better tomorrow than we are today.”

Participants suggested needs and solutions for BEEF focus areas including transportation, assembly/disassembly, maintenance and sustainment, and LCD movement.

These notes are being compiled by STRIKEWERX into an output document with suggested requirements for the BEEF project and will be delivered to AFNWC and AFGSC.

1st Lt. Joseph Puglisi, engineer at the AFNWC system programs office, said the workshop had value in getting a varied perspective on the problem.

“We expected to figure it out as we went along, but the structure meant there were a lot of eyes on all the requirements, which is a lot more helpful than the process that we used,” he said.

Kyle Dell’Aquila, chief of industrial design for Rise Robotics, said entities like STRIKEWERX lower the bar for businesses, like his, to engage with government via events like the BEEF Problem Definition Workshop.

“The problem definition workshop process is a lot more engaging than how it’s traditionally done. Usually, it’s very slow, boring, and procedural, and this is an enhancement of that,” he said. “It makes the exploration of these serious problems really palatable by lowering the bar for entry.”