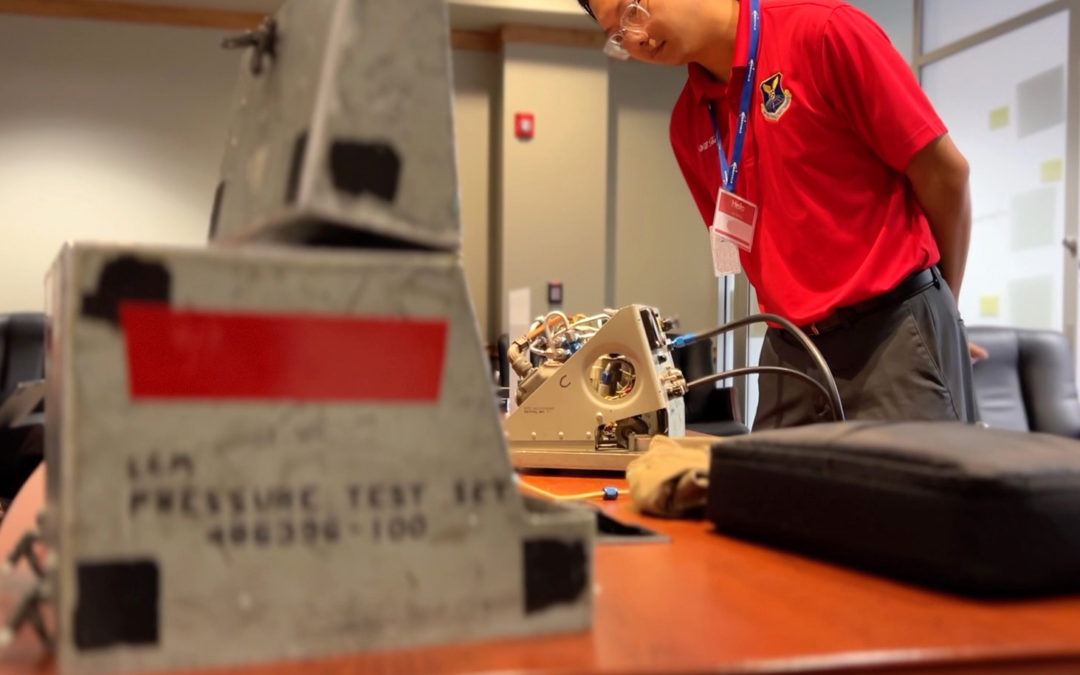

Will Tsao, Electronic Warfare Pressure Test Set maintenance and sustainment project champion, inspects the test set hardware during a problem definition workshop held Oct. 4 in STRIKEWERX at the Cyber Innovation Center, Bossier City, Louisiana. (Sean Green, STRIKEWERX)

By Sean Green | STRIKEWERX Marketing and Communication Director

BOSSIER CITY, La. — STRIKEWERX, Air Force Global Strike Command’s innovation hub, is seeking solutions for redesigning equipment that sustains America’s deterrence.

STRIKEWERX hosted a Problem Definition Workshop at the Cyber Innovation Center in Bossier City, Louisiana, Oct. 4. The workshop saw subject matter experts from government join 20-plus academia and industry participants to assist AFGSC with market research for the Electronic Warfare Pressurizing Test Set.

The EWPTS is used to test the defense system of the B-52 aircraft.

Senior Airman Matheu Taylor, electronic warfare journeyman at Barksdale Air Force Base, Louisiana, went further to explain that this piece of equipment tests the main defense system of their aircraft.

“If that system is faulty, America would lose an arrow in the quiver of its deterrence,” Taylor said.

The B-52 fleet performs an average of 13 pressure tests per month, consuming 2,392 hours per year.

Broken pressure testing equipment increases testing time by three hours. Repairing a faulty test set takes more than four hours with only a 40% success rate.

AFGSC is seeking a portable design that is easier to repair, easier to use in diagnosing equipment failure and allows for greater availability in extreme weather.

The Problem Definition Workshop uses collaboration techniques to have industry, small businesses and academia provide the ideas and technology to combat obstacles faced by the U.S. Air Force.

Tech Sgt. Mianicole Grosshart, EW systems manager at Barksdale AFB, said the workshop was the right mixture of creative minds, subject matter experts and industry experts.

“This workshop was exactly what we needed in terms of innovation, and we were able to collaborate with people we would have never met without STRIKEWERX,” Grosshart said. “The insight these industry experts had was highly crucial for enlightening us to new possibilities.”

Monica Riggs, engineering manager for United Dynamics, said the biggest advantage of participating in this type of workshop is engagement with the end user.

“What is that maintainer seeing and where is the heartburn coming from? Typically, you jump right into the contract and assume, because you’re not able to talk with that end user who is working with the hardware,” Riggs said. “The more we can talk before money is on the table, the better we can meet the requirements and price it.”

STRIKEWERX is compiling the workshop input into a Request for Proposal that will be sent to select industry. Ultimately, the awarded vendor will provide an updated EWPTS prototype for AFGSC.